Power Pucks® harvest energy to power GE wSIM Essential Insight.mesh devices for maintenance free operation throughout the life of the device being powered. Using readily available warm-to-the-touch heat from operating equipment such as pumps, fans and motors, Power Pucks continuously convert temperature difference into electric energy. A temperature difference of 20°C / 68°F between the warm surface and ambient air provides ample power to meet the requirements of GE wSIM devices.

Designed to meet GE’s rigorous standards, Power Pucks eliminate battery replacements, allow increased update rates, and offer a worry-free alternative for operating your wireless sensor networks for decades.

Power for the life of the transmitter

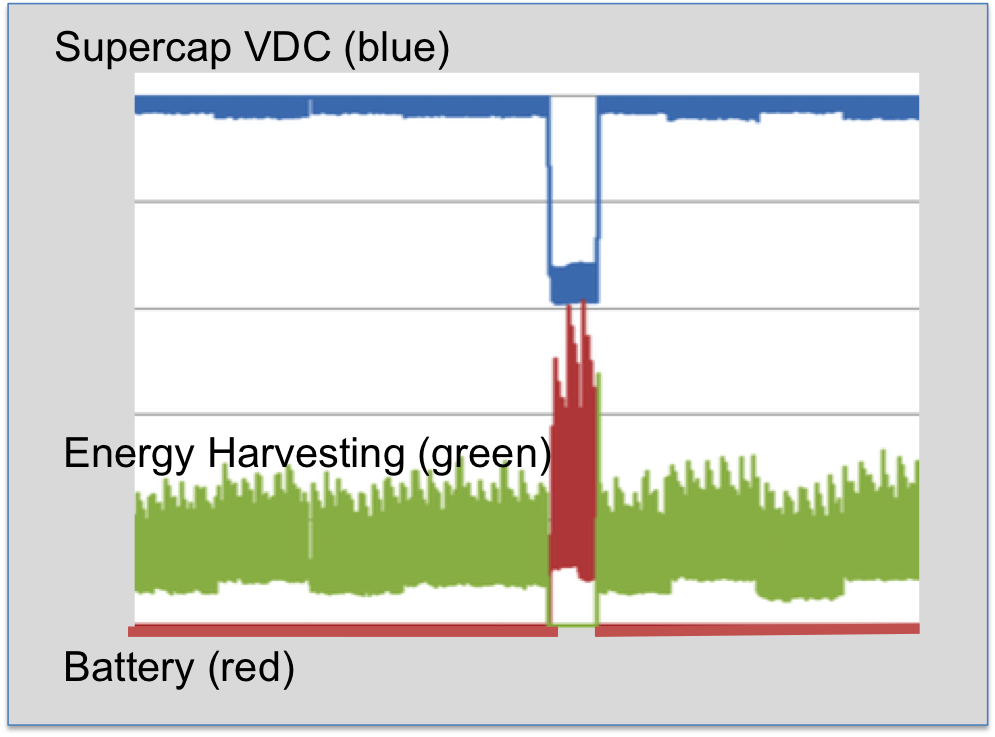

Power Pucks offer a self-sustaining system that eliminates or greatly reduces the need to replace batteries in GE transmitters. This chart shows how energy harvesting seamlessly shifts between energy harvesting and the battery back-up to meet the power requirements of the transmitter. Energy harvesting (green) = Primary power source. Battery contribution (red) = Standard back-up for energy harvesting when the power source is removed. Only a small temperature difference is required to fully power the transmitter. This amount of temperature difference is easily achieved with most any industrial equipment that is warm to the touch.

Easily installed

Installing thermal energy harvesters for GE wireless is a simple three step process and can be completed in less than a minute.